Understanding Modern Warehouse Inventory Management

Think of your warehouse inventory management like the conductor of an orchestra. When the conductor is skilled and precise, the music flows beautifully. But a clumsy conductor? The music becomes a chaotic mess. Similarly, effective inventory management orchestrates the flow of goods, ensuring a harmonious operation. Today, smart companies are transforming their warehouses from mere storage units into strategic hubs, all thanks to a focus on top-notch inventory management.

The Evolution of Warehouse Inventory Management

Remember the days of clipboards and endless manual counting? Thankfully, warehouse inventory management has come a long way. It's no longer about simply storing boxes. Now, successful businesses view their warehouses as dynamic, interconnected systems. Technology, people, and processes work together, much like gears in a well-oiled machine, maximizing efficiency and minimizing costly errors.

For example, imagine a warehouse using a Warehouse Management System (WMS). This system acts like a digital eye, tracking every item in real time – from arrival to shipment. A good WMS helps optimize storage space and even predict future demand, enabling smarter purchasing decisions and reducing the risk of stockouts or overstocking. Curious to learn more about effective warehouse strategies? Check out this guide: Warehousing and Distribution Mastery: Your Complete Guide

From Reactive to Proactive: A Critical Shift

The California warehouse industry learned a valuable lesson about efficient inventory management during the 2021-2022 storage crisis. Surging consumer demand and supply chain disruptions exposed the fragility of many existing systems. Ports like Los Angeles and Long Beach overflowed with waiting ships, mirroring the strain on inland storage facilities. This crisis underscored the vital need for strategic warehouse development and streamlined inventory management. Discover more insights on the legal aspects of warehousing.

This experience forced a crucial shift in mindset: from reactive to proactive. Instead of constantly putting out fires, leading companies are now anticipating them. They leverage data-driven insights to fine-tune their processes, predict demand fluctuations, and make informed choices, much like a chess player anticipating their opponent's moves.

The Benefits of Modern Warehouse Inventory Management

Modern warehouse inventory management offers a wealth of benefits:

-

Increased Efficiency: Imagine a well-organized kitchen: everything is in its place, making cooking faster and easier. Similarly, streamlined processes and automation in a warehouse reduce wasted time and resources.

-

Improved Accuracy: Real-time tracking and data analysis minimize errors, ensuring accurate inventory counts and reducing discrepancies.

-

Reduced Costs: Optimized storage, minimized waste, and efficient operations all contribute to lower overall expenses.

-

Enhanced Customer Satisfaction: Faster order fulfillment and on-time deliveries create happy customers.

-

Greater Agility: Data-driven insights and flexible processes empower businesses to adapt quickly to market changes, like a ship navigating through changing currents.

By embracing modern warehouse inventory management practices, companies can turn their warehouses into powerful assets that fuel growth and profitability. This strategic approach positions them for success in today's ever-changing business environment.

Essential Components That Drive Warehouse Success

Think of your warehouse as a well-oiled machine. Every part needs to work smoothly with the others, or the whole operation grinds to a halt. Let's break down the key elements of a successful warehouse, starting with the fundamentals: receiving and putaway. These initial steps set the tone for everything else.

Just like a chef needs ingredients prepped and ready to go, a warehouse needs a smooth receiving process. This ensures incoming goods are accurately recorded, checked for any damage, and swiftly moved to their designated spots.

The Importance of Efficient Receiving and Putaway

Imagine a library with books shelved randomly – what a mess! A well-organized putaway process makes sure items land in the right location quickly. This minimizes hunting time and maximizes storage capacity. Think high-demand items near the shipping area, cutting down travel time and speeding up order fulfillment. For example, a warehouse handling perishable foods would prioritize getting refrigerated items into cold storage immediately.

Storage System Design: The Backbone of Your Operation

Your storage system is the backbone of your warehouse—its efficiency dictates the entire operation's flow. A poorly planned system creates bottlenecks, wasted space, and higher handling costs. Think of a crammed closet versus a well-organized walk-in wardrobe. One is a nightmare, the other a dream. Effective storage involves making the most of vertical space, optimizing aisle widths for forklifts and other equipment, and using clear signage for easy navigation.

You might be interested in: 5 Essential Warehousing Services Offered by WAFF Logistics

Picking and Packing: The Customer-Facing Operations

Picking and packing are where the magic happens – these processes directly impact customer happiness. A streamlined picking process reduces errors, gets orders out the door faster, and keeps customers coming back. Imagine ordering dinner at a restaurant – a wrong dish or slow service equals unhappy diners. Similarly, picking mistakes or slow packing lead to incorrect shipments, delays, and eventually, lost customers. Investing in tools like barcode scanners and pick-to-light systems can significantly improve picking accuracy and speed.

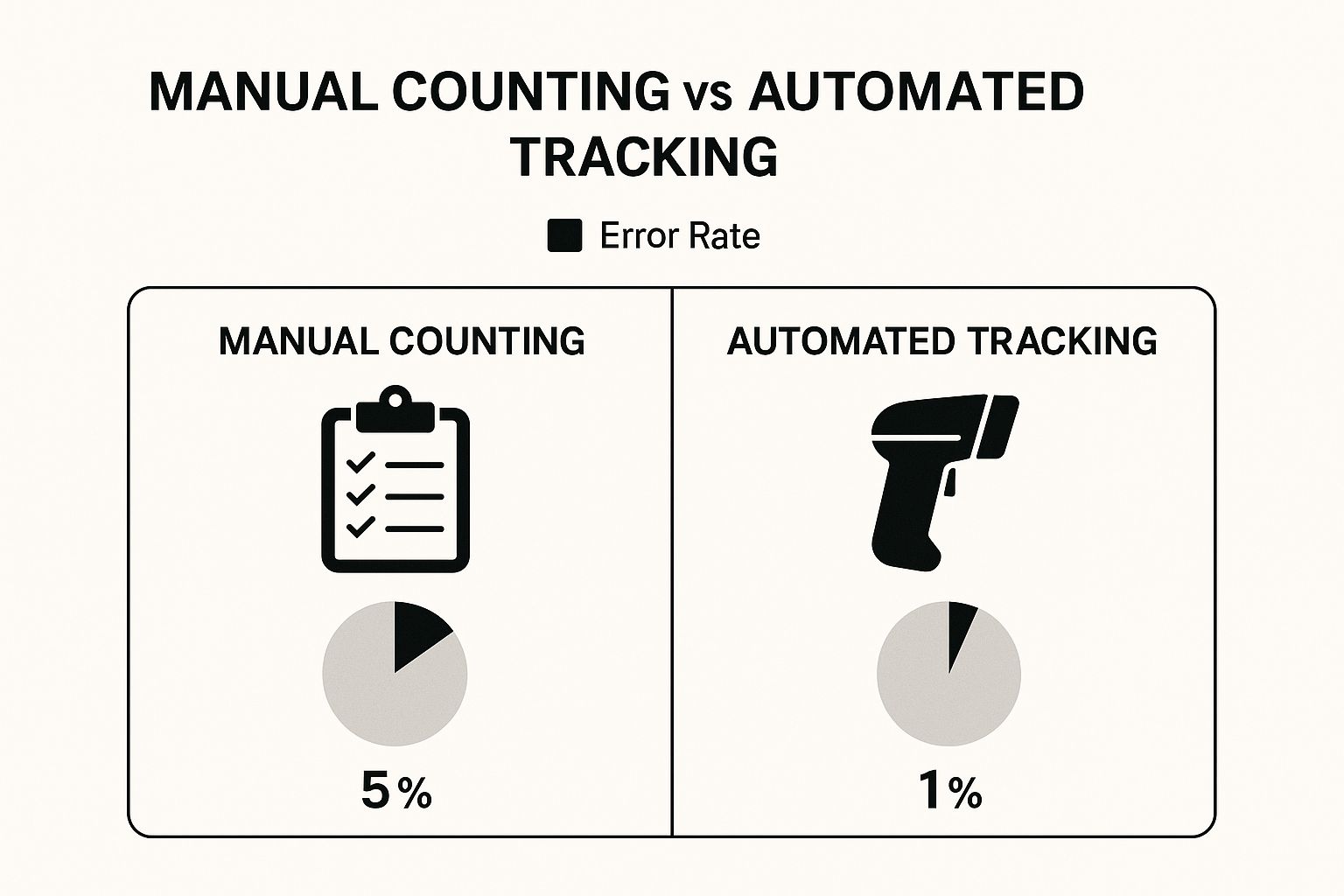

Let's take a look at how automation impacts accuracy with this infographic:

The data shows that manual counting results in a 5% error rate, while automated tracking significantly reduces errors to 1%. This demonstrates the power of automation to improve accuracy and lower the costs of incorrect shipments and returns.

To further illustrate the difference between traditional and modern warehouse operations, let's look at this comparison table:

Core Warehouse Operations Comparison

| Operation | Traditional Method | Modern Approach | Efficiency Gain | Technology Used |

|---|---|---|---|---|

| Receiving | Manual paperwork, visual inspection | Automated data entry, RFID tags | Reduced processing time, fewer errors | Warehouse Management System (WMS), RFID readers |

| Storage | Static shelving, manual inventory tracking | Dynamic slotting, real-time inventory updates | Increased storage capacity, optimized product placement | WMS, automated storage and retrieval systems (AS/RS) |

| Picking | Paper pick lists, manual cart pushing | Digital pick lists, voice picking, automated guided vehicles (AGVs) | Faster picking speeds, improved accuracy | WMS, mobile devices, voice picking software, AGVs |

| Shipping | Manual labeling, paperwork for carriers | Automated labeling, integrated shipping software | Streamlined shipping process, reduced shipping errors | WMS, shipping software integrations |

This table highlights how modern technology significantly improves the efficiency of key warehouse operations.

Optimizing Each Component for Peak Performance

Each part of your warehouse—receiving, putaway, storage, picking, and packing—plays a vital role in the bigger picture. By optimizing each process and ensuring they work together flawlessly, you create a high-performing warehouse that boosts efficiency, satisfies customers, and strengthens your bottom line. Just like a championship team, every player (component) has to perform their role effectively for the team (warehouse) to win (succeed). These optimized processes help warehouses handle peak seasons, unexpected surges in demand, and the constant pressure for ever-faster fulfillment.

Technology That's Transforming Warehouse Operations

This screenshot gives you a glimpse into a typical Warehouse Management System (WMS) interface. Notice the level of detail—inventory levels, order status, location tracking—it's all there. This real-time data is like giving warehouse managers a superpower, allowing them to make smart decisions and optimize every aspect of their operations.

Today, running a successful warehouse means embracing technology. These tools aren't just nice-to-haves; they're the backbone of modern inventory management and crucial for staying competitive. Let's dive into the key technologies reshaping the industry.

The Central Nervous System: Warehouse Management Systems (WMS)

Imagine the WMS as the central nervous system of your warehouse. It connects and controls everything: receiving shipments, managing storage, orchestrating picking and packing, and tracking orders all the way to the customer's doorstep. A powerful WMS gives you a real-time view of every single item in your inventory, enabling proactive management and data-driven decisions. This is a total game-changer for any business looking to streamline its supply chain. Even something as seemingly simple as product labeling, often handled through specialized Packaging Labels Printing, becomes more efficient within this integrated system.

Let's say you suddenly see a huge spike in demand for a specific product. Your WMS can pinpoint its exact location in the warehouse, guide pickers directly to it, and automatically update inventory counts as the order is fulfilled. No more guessing games, fewer errors, and faster, more accurate shipping. And this shift towards WMS technology isn't slowing down. By 2025, over 90% of businesses are predicted to be using WMS to automate their processes, giving them a significant competitive edge. Learn more about these trends. This integration of advanced inventory management software with other systems, including robotics, is a recipe for increased efficiency, reduced errors, and a major boost in overall productivity.

Real-Time Visibility: Barcode Scanning, RFID, and IoT

Beyond the WMS, technologies like barcode scanning, RFID (Radio-Frequency Identification), and IoT (Internet of Things) sensors create a smart, interconnected warehouse environment. Barcode scanners provide fast and accurate product identification, while RFID tags take it a step further, offering real-time tracking without even needing a direct line of sight. Think of RFID like a GPS for your inventory – you know exactly where everything is, all the time.

IoT sensors add another layer of intelligence. Embedded in equipment and throughout the warehouse, these sensors constantly monitor things like temperature, humidity, and even equipment performance. This constant stream of data allows for predictive maintenance, optimized storage conditions (especially important for sensitive items), and significant improvements in overall operational efficiency. For instance, a temperature sensor in a cooler could alert you to a potential equipment malfunction before any products spoil, saving you money and preventing disruptions. This real-time visibility translates to smoother operations and happier customers.

Automation and Robotics: The Future of Warehouse Work

Automation and robotics are transforming warehouse work as we know it. Automated guided vehicles (AGVs) move goods around autonomously, freeing up human workers from repetitive tasks. Robotic arms assist with picking and packing, increasing both speed and accuracy while also making the workplace safer. This doesn't just improve efficiency; it lets your employees focus on more complex tasks that require critical thinking and problem-solving. The result? A more engaging and rewarding work environment, happier employees, and increased productivity. Plus, these technologies enable 24/7 operation, allowing you to fulfill orders faster and keep up with the ever-growing demands of e-commerce. The future of warehouse work is here, and it's making operations more efficient, safer, and more fulfilling.

Performance Metrics That Actually Drive Results

This dashboard shows how different key performance indicators (KPIs) work together to give you a complete picture of your warehouse’s performance. Think of it like the dashboard in your car. It gives you instant feedback on your speed, gas mileage, and how well the engine is running. Just like a driver needs to keep an eye on those gauges, warehouse managers need to track KPIs to ensure everything is running smoothly. But it's not just about collecting data. Understanding what those numbers mean is what allows you to make smart decisions.

Inventory Accuracy: The Foundation of Customer Trust

Imagine ordering a bookshelf online and receiving a desk. Pretty frustrating, right? Inventory accuracy is about more than just having the correct numbers in your system. It's the bedrock of customer trust. Accurate inventory data is essential for getting orders out on time, preventing shipping mistakes, and ultimately, keeping customers happy. When your inventory is accurate, you can also plan better and use your resources more effectively. It's not about striving for absolute perfection, but about building a reliable system that minimizes errors and gives you confidence in your operations, leading to repeat business from satisfied customers.

Order Fulfillment Speed: Time Is of the Essence

In today’s world, customers expect quick deliveries. Order fulfillment speed, the time it takes to get an order from placement to delivery, has a direct impact on both customer satisfaction and your bottom line. Think of it as a relay race – every second counts. Faster fulfillment means happier customers and quicker payments, which strengthens your company’s financial health. The goal isn’t just to rush, but to streamline your processes, remove bottlenecks, and make sure orders are processed quickly and efficiently. For those looking to optimize their speed further, Efficient Cross-Docking Service might be a helpful resource.

Inventory Turnover Rate: Striking the Right Balance

Imagine a grocery store stocking fresh produce. They want it to fly off the shelves before it goes bad. Inventory turnover rate measures how often you sell and replace your inventory within a given timeframe. A high turnover rate is usually a good sign – it indicates strong sales and efficient stock management. But a turnover rate that's too high could mean you're understocking and potentially losing sales. Using technology like AI in Field Service can dramatically improve warehouse efficiency. The key is to find the right balance for your business, one that minimizes storage costs while still meeting customer demand. This metric helps you analyze your demand forecasting and make the best use of your storage space.

Using KPIs to Drive Improvement

So, how do you actually use these metrics? First, you need to set realistic targets, or benchmarks, based on industry averages and your own operational capabilities. Then, track your performance against these benchmarks using a Warehouse Management System (WMS). A good WMS acts as your central data hub, providing a real-time view of these key metrics. Regularly reviewing this data allows you to identify trends, spot potential problems, and make informed decisions. This helps you refine your processes, anticipate challenges, and uncover opportunities to improve. Consistent monitoring and analysis empower you to make proactive decisions that lead to real, positive results.

The following table provides a practical overview of essential warehouse KPIs, including industry benchmarks, calculation methods, improvement strategies, and their potential impact:

Essential Warehouse KPIs Dashboard

Key performance indicators with industry benchmarks, calculation methods, and improvement strategies for warehouse inventory management

| KPI | Industry Benchmark | Calculation Method | Improvement Strategy | Impact Level |

|---|---|---|---|---|

| Inventory Accuracy | 95% - 99% | (Inventory on Hand / Recorded Inventory) * 100 | Cycle counting, regular audits, barcode scanning | High |

| Order Fulfillment Speed | 24-48 hours | Time from order placement to delivery | Process optimization, automation, improved picking & packing processes | High |

| Inventory Turnover Rate | Industry-specific (e.g., 6-12 for retail) | (Cost of Goods Sold / Average Inventory Value) | Demand forecasting, inventory control techniques, optimized storage | Medium |

| Order Picking Accuracy | 99% + | (Correctly Picked Orders / Total Orders Picked) * 100 | Implement barcode or RFID scanning, staff training, double-checking systems | Medium |

| Storage Capacity Utilization | 80% - 90% | (Space Used / Total Available Space) * 100 | Optimize layout, vertical storage solutions, slotting optimization | Medium |

This table summarizes key warehouse KPIs and provides a framework for improvement. By focusing on these metrics and implementing the suggested strategies, you can significantly enhance your warehouse operations and drive better overall business results.

Success Stories From The Warehouse Floor

Let's step away from the textbooks and look at how real companies have achieved success with their warehouse inventory management. These stories show how different businesses, facing unique hurdles, turned their operations around through smart planning and execution. They bring to life the concepts and technologies we've been discussing.

From Chaos to Control: An E-commerce Breakthrough

Picture a fast-growing e-commerce company struggling to keep pace with incoming orders. Their warehouse was a hive of activity, but it was disorganized and inefficient. Misplaced items, late deliveries, and unhappy customers were commonplace. Does this sound familiar? This company adopted a cloud-based WMS and started using barcode scanners. This seemingly small change had a huge impact. By having a real-time view of their inventory, they could optimize picking routes and streamline their packing process. The result? They tripled their order fulfillment capacity with the same number of employees. They moved from constantly putting out fires to running a smooth, controlled operation, greatly improving both customer satisfaction and profits.

Preventing Stockouts: A Manufacturer's Triumph

A mid-sized manufacturer was constantly struggling with stockouts, disrupting production and hurting their relationships with customers. They realized their demand forecasting wasn't accurate, and their safety stock levels weren't sufficient. By adopting a more advanced demand forecasting model that considered past data, seasonal trends, and even outside factors like the economy, they gained a much better understanding of future demand. They also implemented smart safety stock management, making sure they had enough buffer stock to deal with unexpected changes without tying up too much capital. This two-pronged approach practically eliminated stockouts, resulting in smoother production runs, better on-time delivery rates, and stronger customer partnerships.

Cutting Costs: A Distributor's Strategic Advantage

A regional distributor was dealing with increasing operating costs that were eating into their profits. They knew they needed to make a change. They wisely invested in warehouse automation, introducing automated guided vehicles (AGVs) for moving materials and robotic arms for picking and packing. This not only increased speed and accuracy but also lowered labor costs. They also redesigned their warehouse layout to make the best use of space and reduce travel time. By combining these strategies, they cut their operational expenses by almost one-third, improving their profitability and giving them a competitive edge. One of the biggest challenges facing California's inventory warehousing industry is the high cost of real estate. These prices can be a real obstacle for businesses wanting to set up or expand their warehousing operations. However, despite these challenges, the Warehouse Clubs & Supercenters industry in California is expected to grow significantly, reaching a market size of around $90.8 billion by 2025. Discover more insights.

Learning From Real-World Success

These examples show how powerful effective warehouse inventory management can be. They aren't just theoretical scenarios; they offer practical lessons you can apply to your own business. Each story highlights the importance of understanding your specific challenges, finding the right technologies and approaches, and making decisions based on data to achieve real improvement. By learning from these successes, you can create your own roadmap to warehouse excellence.

Avoiding Costly Warehouse Management Mistakes

Even with the best laid plans, warehouse operations can stumble into some pretty expensive traps. These errors not only drain resources and frustrate your team, but they hit your bottom line hard. So, let’s explore a few common pitfalls and how to avoid them.

The Manual Trap: Sticking With Outdated Processes

Imagine trying to navigate a busy highway in a horse-drawn carriage. That's what it's like for warehouses clinging to manual processes in today's fast-paced world. While pen and paper might have sufficed in the past, relying on them now for things like inventory counting is not just slow, it’s an invitation for errors.

Think of the time wasted – time that could be spent on more strategic tasks. A robust Warehouse Management System (WMS) is the modern-day equivalent of a high-performance vehicle, enabling automation that saves significant time and money. Recognizing where manual processes are holding you back is the first step toward real efficiency gains.

The Tech Trap: Implementing Technology Without a Plan

Buying a powerful sports car is exciting, but it won't do you much good if you don't know how to drive it. Similarly, implementing new technology without proper planning and change management can be a recipe for disaster. You might have the latest and greatest tools, but without a clear strategy and comprehensive team training, they won't deliver the promised results.

A smooth transition requires a well-defined implementation plan. This includes making sure your staff is properly trained and comfortable using the new system. Investing in training upfront will pay dividends down the road by ensuring you get the most out of your tech investment.

The Cost-Cutting Trap: Focusing on Price Over Value

We all like to save money, but sometimes the cheapest option ends up being the most expensive in the long run. Think about buying the cheapest tools – they might break easily, requiring frequent replacements and ultimately costing more than a higher-quality option. The same principle applies to warehouse management.

Focusing solely on cutting costs instead of creating value can lead to decreased performance, impact employee morale, and ultimately drive up your long-term expenses. It's essential to consider the long-term value and return on investment when making decisions, not just the initial price tag.

Early Warning Signs and Course Correction

How do you know when a small issue is about to become a major headache? One of the best ways is to keep a close eye on your key performance indicators (KPIs). Are order fulfillment times creeping up? Is your inventory accuracy slipping? These could be early warning signs of bigger operational problems brewing beneath the surface.

Talking to other warehouse managers who've faced similar challenges can provide valuable insights and perspective. They can help you identify those early warning signals and take corrective action before things spiral out of control.

Developing solid decision-making frameworks, even when you don't have all the information, is also crucial. Sometimes you have to make the best call you can with what you have. Knowing how to do this effectively, and having a plan for adjusting course when things don't go as planned, is a hallmark of successful warehouse management. By learning from the mistakes of others and building adaptable strategies, you can navigate the complexities of warehouse inventory management and steer your operation toward long-term success.

Your Roadmap To Warehouse Excellence

So, you've got the basics of warehouse inventory management down – great! Now, let's talk about putting that knowledge to work. This isn't about flipping a switch and magically transforming everything overnight. Think of it more like a journey, taking strategic steps, building up speed, and seeing real progress from day one. Whether you're running a small warehouse or a vast logistics network, the key is creating a roadmap that fits your specific situation.

Assessing Your Current Situation: An Honest Look

Before you jump into making changes, take a good, hard look at your current warehouse practices. What are the biggest headaches? Are you constantly running out of stock? Are your picking and packing processes like molasses in January? Do you have a crystal-clear picture of your inventory accuracy? Identifying your weak spots is like a doctor diagnosing a patient before prescribing medicine – it’s the crucial first step to getting better.

Identifying Opportunities and Setting Priorities

Once you've got a handle on your challenges, you can start to see where the biggest opportunities for improvement lie. Which changes will give you the biggest bang for your buck and make your customers happiest? Maybe it's investing in a Warehouse Management System (WMS) or redesigning your warehouse layout for smoother product flow. Don’t forget about mitigating risks! For example, being proactive about construction site theft prevention can save you a lot of headaches (and money) down the line. Prioritize these opportunities based on their potential return on investment and the resources you have available.

Building a Realistic Timeline: Balancing Ambition With Reality

Now, let's talk timelines. Break down those big, ambitious projects into smaller, bite-sized chunks. Set realistic milestones that balance your desire for quick wins with the practical realities of your day-to-day operations. Maybe you phase in new tech over a few months, or roll out process changes one department at a time. A realistic timeline keeps your team focused and motivated while minimizing disruptions to your workflow. Remember, even small victories build momentum toward long-term success.

Technology Investments That Pay Off: Choosing Wisely

Technology can be a real game-changer, but not all tech is created equal. When considering new technology, think about your specific needs and where you want to be in the future. Will that shiny new WMS play nice with your current systems? Do you have the infrastructure to support automation? Figure out the potential return on investment and choose solutions that genuinely add value and fit into your overall strategy. It’s like choosing the right tool for the job – using a hammer to tighten a screw won’t get you very far. And speaking of California, the rules of the game are changing. In response to some serious warehouse challenges, Assembly Bill 98, passed in September 2024, is bringing new requirements for warehouses over 250,000 square feet, starting January 1, 2026. The goal? Creating “21st-century warehouses” ready for the demands of modern supply chains. Learn more about these regulations.

Team Buy-In: Fostering Collaboration and Ownership

Change can be unsettling. That’s why getting your team on board is so important. Involve your employees in the planning process, listen to what they have to say, and clearly explain the benefits of the changes you’re making. When your team understands the why and the how, they’re much more likely to embrace the new ways of doing things. This builds collaboration and a sense of ownership, making implementation smoother and delivering better results in the long run.

Measuring Progress and Maintaining Momentum: The Long Game

Making changes is just the first step. You need to continuously track your progress against your key performance indicators (KPIs). Regularly review your data, celebrate wins, and identify any areas where you need to adjust your approach. Warehouse inventory management is a marathon, not a sprint. It's an ongoing process of improving and adapting. As your business grows and the market changes, your warehouse needs to keep pace. By consistently evaluating your performance, you can maintain momentum, refine your strategies, and ensure your warehouse remains a powerful driver of growth.

Ready to take your warehouse operations to the next level and propel your business forward? Partner with Waff Logistics Inc., your one-stop 3PL partner serving businesses across Canada. We offer complete logistics solutions, from warehousing and fulfillment to nationwide delivery, all tailored to your specific industry needs. Learn more about how Waff Logistics can transform your supply chain.

Article created using Outrank