Understanding the Warehousing and Distribution Foundation

Imagine your warehouse as the central hub of your distribution network. It's the place where products come and go, connecting your suppliers with your customers across the entire supply chain. Effective warehousing and distribution isn't simply about stacking boxes; it's about strategically orchestrating the movement of goods to meet customer demand efficiently and affordably. This requires a shift in perspective – seeing your warehouse not as a static cost, but as a dynamic, valuable asset.

Think of it like an orchestra: every instrument, from receiving docks to shipping bays, needs to be perfectly tuned and in sync to create a harmonious flow of logistics.

Key Principles of a Strong Foundation

A robust warehousing and distribution system is built on several interconnected principles:

-

Strategic Location: Location is paramount. Choosing a location with easy access to major transportation arteries, close proximity to your target market, and a readily available workforce can drastically impact your operational efficiency. For example, a warehouse situated near a major interstate and a large metropolitan area can significantly reduce both transportation costs and delivery times. Consider Southern California, a major logistics hub, which boasts roughly 34,000 warehouses and 1.17 billion square feet of warehouse space. This concentration underscores the importance of strategic location. Discover more insights

-

Efficient Layout and Design: The internal layout of your warehouse should be meticulously planned to optimize the flow of goods. Clearly marked pathways, designated storage zones, and a logical progression from receiving to shipping minimize wasted time and effort. Think of it like designing a well-organized kitchen: everything has its place, making the workflow smooth and intuitive.

-

Technology Integration: Employing technology such as a Warehouse Management System (WMS) is essential for real-time inventory tracking, streamlined order fulfillment, and accurate data analysis. A WMS acts like the conductor of your logistics orchestra, ensuring all the different parts work together seamlessly. Understanding processes like ecommerce fulfillment is key to maximizing the effectiveness of your technology investments.

-

Skilled Workforce: A well-trained team is the backbone of any successful warehousing and distribution operation. Your employees need to be proficient in using warehouse technology, operating equipment safely, and executing processes efficiently. For further reading on the topic of warehousing expertise, check out: Warehousing in Canada: How U.S. Medical Manufacturers Benefit

-

Cost Optimization: Managing costs without sacrificing service quality is vital. This involves streamlining processes, negotiating competitive shipping rates, and minimizing waste throughout your entire supply chain.

Visualizing Warehouse Operations

This image from Wikipedia provides a visual representation of various aspects of warehousing, from storage layouts and equipment to the overall scale of these operations. It illustrates the complexity of managing a warehouse effectively, highlighting the need for strategic planning and meticulous organization. Optimizing each of these facets is crucial for a smoothly functioning distribution network.

By effectively integrating these foundational principles, you create a warehousing and distribution system that is not only efficient but also flexible enough to adapt to the ever-evolving demands of the market. This adaptability allows your business to compete effectively, provide excellent customer service, and achieve sustainable growth.

Strategic Location Selection That Creates Competitive Advantage

Picking the right spot for your warehouse is a big decision, one that will affect your business for years to come. Think of it like choosing a location for a retail store. Foot traffic matters, sure, but so do things like easy access and what the competition is doing. For warehouses, it’s not just about finding the cheapest rent. It’s about understanding how location impacts everything from transportation costs and finding good employees to keeping customers happy and planning for future growth.

Beyond the Basics: Unveiling Hidden Advantages

Smart warehouse operators look beyond the obvious when evaluating potential locations. They consider how close a site is to major transportation hubs. That means not just highways, but also rail lines, ports, and airports. Being near a major airport, for instance, can be a huge plus for businesses that need to ship things quickly or deal with international trade. And having access to a strong local transportation network is essential for smooth last-mile deliveries.

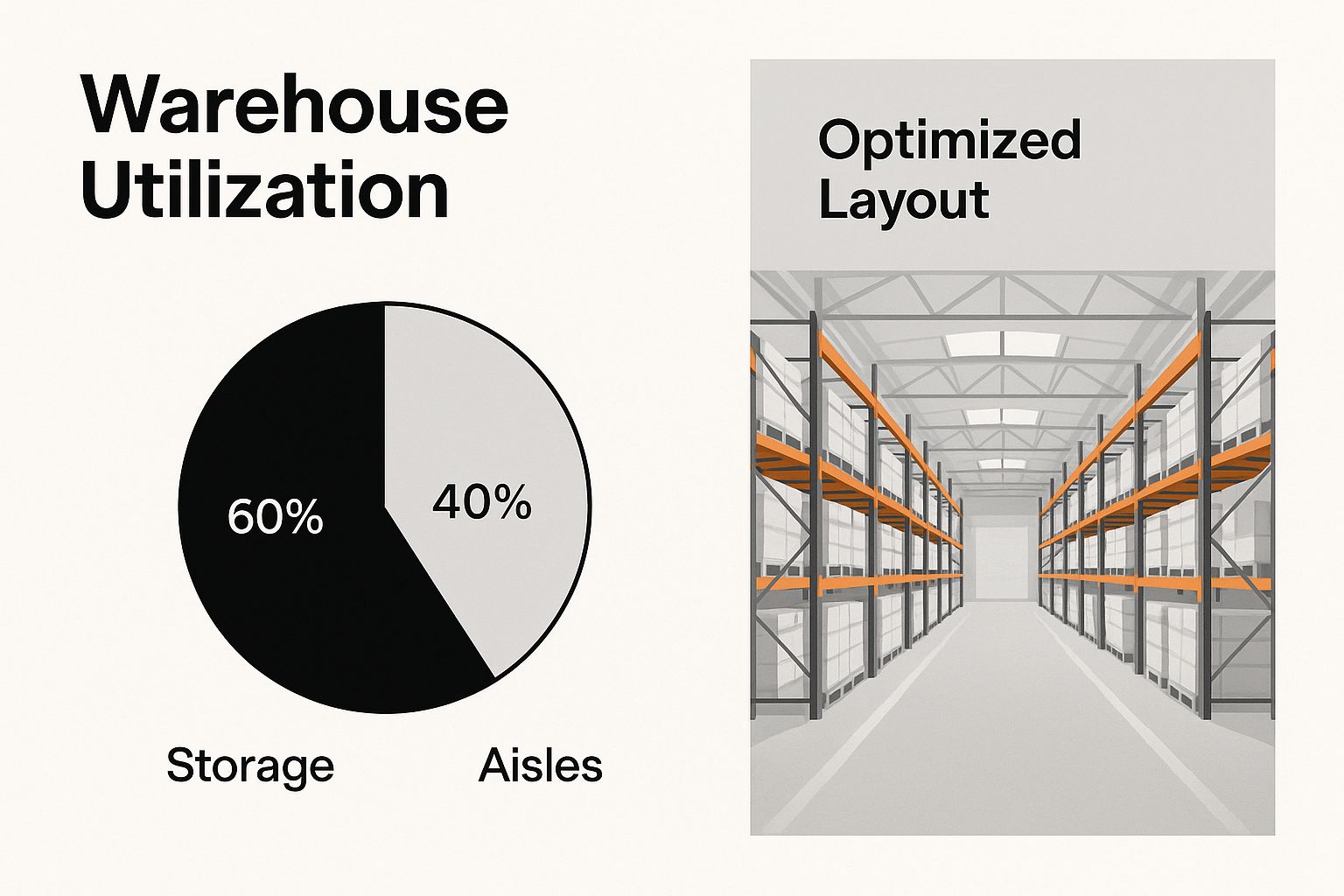

This infographic shows how a well-organized warehouse layout can make the most of available space and improve the flow of operations. A good layout cuts down on wasted space and travel time, which directly impacts productivity and how efficiently the warehouse runs.

Labor Markets and Regional Dynamics

Finding qualified workers is another key piece of the puzzle. If your warehouse is in an area with a small labor pool, you might struggle to hire people and end up paying more for labor. On the other hand, a region with a growing warehouse sector usually offers a larger and more accessible talent pool. One example is California's Central Valley, where the warehouse industry, especially the big-box market, is booming. The warehouse workforce there is expected to grow by 17.8% by 2034, which is good news for businesses looking to expand. Discover more insights.

Regional economic conditions, tax breaks, and regulations also influence location decisions. An area that's friendly to businesses can offer significant perks, like lower operating costs and less red tape. That’s why many companies are drawn to specific areas known for supporting logistics operations.

To help illustrate the impact of location, let's take a look at a comparison of a few key regions:

Regional Warehouse Location Comparison

This table compares key factors across different warehouse regions, highlighting costs, labor availability, and strategic advantages.

| Region | Average Cost per sq ft | Labor Growth Rate | Transportation Access | Market Demand |

|---|---|---|---|---|

| Example Region A | $X | Y% | High | Strong |

| Example Region B | $XX | YY% | Medium | Moderate |

| California's Central Valley | $XXX | 17.8% | High | High |

As you can see, different regions offer different advantages and disadvantages. California's Central Valley, for example, benefits from strong market demand and a robust labor pool, while other regions might offer lower costs but less growth potential.

The Long-Term View: Adapting to Change

Successful businesses think about the future when choosing a warehouse location. They consider how their needs might change over time and how the market might evolve. They pick locations that offer flexibility and room to grow. A spot that seems perfect now might become a problem later if there's no space to expand or if it can't keep up with changing customer demands. Taking the long view ensures that location decisions remain valuable assets, giving your business a competitive edge for years to come.

Designing Warehouse Operations That Actually Flow

Imagine your warehouse not just as a storage space, but as a living, breathing organism. Goods move like blood cells, constantly flowing through its arteries and veins. A well-designed warehouse ensures this flow is smooth and efficient, preventing any logistical "blood clots" that can slow things down. This isn’t just about a tidy space; it’s about creating a warehousing and distribution system that truly performs. In this section, we’ll explore the core components of efficient warehouse operations, going beyond blueprints to see how real-world warehouses optimize their layout and design.

The Art of Flow: From Receiving to Shipping

The journey of a product through your warehouse should be as seamless as a well-rehearsed dance. Think of it like a river – it needs a clear path from its source (your receiving dock) to its final destination (the shipping bay). Each stage, from storage and picking to packing, must be carefully orchestrated to minimize wasted movement.

Let’s say your warehouse receives goods at one end and ships them from the other. Storing fast-moving items near the receiving dock would mean workers constantly crisscrossing the warehouse to fulfill orders. This adds unnecessary time and expense. By placing high-demand items closer to shipping, you drastically cut down on travel time and boost productivity.

Optimizing Pick Paths: The Secret to Speed

A pick path is the route a worker follows to gather items for an order. Think of efficient pick paths as well-maintained highways, enabling workers to quickly navigate the warehouse. This could involve organizing items by popularity, implementing zone picking, or adopting technology like pick-by-voice systems.

Consider also the physical layout. Narrow aisles and cluttered spaces create bottlenecks, slowing down the entire process. Wide aisles, clear signage, and strategically placed equipment empower workers to move freely and safely, leading to faster picking speeds and fewer errors.

Adaptability: Handling Peaks and Valleys

Warehouse operations rarely experience consistent volume. Demand ebbs and flows, creating peaks and valleys throughout the year. A truly efficient warehouse design anticipates and accommodates these fluctuations. This could involve flexible storage solutions that adapt to changing demand or cross-trained employees who can handle multiple roles.

This adaptability is key for peak seasons. A rigid system can easily get overwhelmed, leading to delays and errors. A flexible warehouse can adapt to volume changes, maintaining smooth operations even during the busiest periods. For more information on available warehousing services, check out our guide on: 5 Essential Warehousing Services Offered by WAFF Logistics.

Technology Meets Design: The Modern Warehouse

Technology plays a crucial role in optimizing modern warehouse design. Warehouse management systems (WMS) provide real-time visibility into inventory and order status, allowing for dynamic adjustments to pick paths and storage strategies. Automated systems, such as conveyor belts and robotic picking systems, further enhance efficiency by streamlining repetitive tasks.

This integration of technology and design creates a warehousing and distribution system that is not only efficient but also highly responsive. This means businesses can quickly adapt to changing market demands and customer expectations.

The following table, "Warehouse Design Elements Impact Analysis," demonstrates how various design choices can significantly affect operational efficiency, costs, and productivity metrics.

| Design Element | Efficiency Impact | Cost Consideration | Implementation Complexity | ROI Timeline |

|---|---|---|---|---|

| Optimized Pick Paths | High | Moderate | Low | Short-Term |

| Flexible Storage | Medium | High | Medium | Mid-Term |

| WMS Integration | High | High | Medium | Long-Term |

| Automation | High | Very High | High | Long-Term |

This table provides a snapshot of how design choices influence warehouse operations, offering valuable insights for strategic planning. While automation offers substantial long-term gains, it requires significant upfront investment. Optimized pick paths provide quick wins with relatively low implementation complexity. Each element presents a trade-off between cost, complexity, and the resulting efficiency gains.

By carefully considering these elements, you can design warehouse operations that are not only efficient but also contribute significantly to your business's bottom line.

Technology Integration That Delivers Real Results

Technology in warehousing isn't about flashy robots; it's about empowering your team and delighting your customers. Choosing the right tech is like selecting the perfect tool for a job – it needs to be effective, not just impressive. This section explores how successful warehousing operations evaluate technology and build systems that grow with their business.

Warehouse Management Systems: The Central Nervous System

A Warehouse Management System (WMS) is the heart of modern warehousing. Think of it as the central nervous system, coordinating everything from receiving inventory to managing shipments. A WMS offers real-time visibility into stock levels, tracks orders, and optimizes workflows. Without a WMS, you're navigating in the dark, relying on manual processes prone to errors and delays.

This screenshot from Wikipedia shows a typical WMS interface. It highlights key functions like inventory management, order processing, and reporting. These modules show how a WMS helps businesses manage all parts of their warehouse from one place. A robust WMS empowers you to make data-driven decisions, improving your warehouse layout, streamlining workflows, and boosting efficiency.

Automation: Not Just Robots

Automation in warehousing is more than just robots. It's about automating tasks to reduce manual work and improve accuracy. This could be conveyor belts moving goods, automated picking tools, or software that automatically creates shipping labels. The best automation tools depend on your specific needs and products. For example, if you handle lots of small items, automated sorting systems might be beneficial. If you deal with large, bulky goods, automated guided vehicles (AGVs) could be a better fit.

Data Analytics: Turning Information into Insight

Data is essential for modern warehousing. Collecting and analyzing data helps you spot trends, identify bottlenecks, and improve operations. A good WMS gives detailed reports on key metrics like order fulfillment times, inventory turnover, and storage space use. Understanding these metrics helps you make smart decisions. For example, if your data reveals lots of picking errors in one area, you can look at the layout or picking processes in that zone.

Avoiding Technology Pitfalls: Focus on ROI

Investing in technology means carefully looking at return on investment (ROI). Not every new tool will help your business. Assess your needs, understand the potential benefits, and calculate the expected ROI. Don't fall for marketing hype. Focus on the real benefits for your operations. For example, if a new WMS costs $100,000 but saves $150,000 a year in labor, the ROI is clear.

Building a Scalable System: Planning for Growth

When choosing technology, think about your future. A system that works now might not work later. Choose solutions that can grow with your needs. This could mean a cloud-based WMS that handles increasing data or modular automation equipment that can expand as your business does. Planning for scalability avoids expensive upgrades later. This forward-thinking approach is key to long-term success. A flexible system helps you adapt to market changes and stay competitive. For example, a modular conveyor system can be easily adjusted for new products or more orders. This adaptability is essential for efficient operations and happy customers.

Distribution Network Design That Serves Your Strategy

Think of your distribution network not just as a way to move boxes, but as the lifeblood of your business. It's the system that delivers on the promises you make to your customers. Just like a river network, it needs to flow smoothly and efficiently to reach everyone it serves. Creating a successful distribution network takes careful planning, strategic thinking, and understanding how all the pieces fit together. Let's explore how companies design these networks and tailor them to their specific needs.

Matching Network Design to Business Strategy

Your distribution strategy should be a direct reflection of your overall business goals. Imagine two companies: one promises same-day delivery and competes on speed, while the other focuses on keeping costs low. They'll need very different distribution setups. The speed-focused business might have a network of smaller warehouses closer to customers. This gets packages out quickly but can be more expensive to maintain. The cost-conscious business, on the other hand, might have one large, central warehouse. This keeps warehousing costs down but means longer delivery times.

California's freight and logistics market is a great example of how important distribution network design is becoming. It's expected to reach USD 223.96 billion by 2030, largely driven by the trucking industry. This growth presents exciting opportunities, but also serious challenges for businesses operating in the state. Discover more insights.

Centralized vs. Decentralized: Choosing the Right Model

There are two main distribution models: centralized and decentralized. A centralized model operates from a single warehouse that serves all customers. This is often the most economical option for businesses with customers clustered in one area, or for those shipping items that don’t spoil. However, it can mean longer wait times for customers farther away.

A decentralized model uses multiple warehouses spread out strategically, closer to where customers live. This approach speeds up delivery and keeps customers happy, but it also increases warehousing expenses and makes inventory management more complex. Choosing the best model depends on several factors, including the type of product, where your customers are located, and the level of service you aim to provide. You might find this interesting: Efficient Cross-Docking Service

The Impact of E-commerce and Customer Expectations

The rise of e-commerce has fundamentally changed the game for distribution networks. Customers now expect their orders to arrive faster, often within a day or two. This has forced businesses to rethink their strategies, leading to wider use of decentralized models and innovative delivery solutions like drop-shipping and micro-fulfillment centers. To improve the effectiveness of technology in your warehouse, consider exploring data integration solutions.

Key Considerations for Network Optimization

When designing or improving a distribution network, here's what you need to think about:

- Customer Density: Where are your customers concentrated? High density in certain areas could justify a dedicated warehouse nearby.

- Product Characteristics: Do you ship fresh produce or items that need special care? This affects storage needs and how you transport your goods.

- Service Level Requirements: How quickly do your customers expect their orders? Faster delivery usually means a more spread-out network.

- Transportation Costs: Look at the costs of different transportation methods—trucks, trains, airplanes—and how they influence your network design.

By carefully considering these factors, businesses can build distribution networks that not only satisfy customers but also provide a competitive edge. This strategic approach makes your distribution system a powerful engine for growth and profitability.

Cost Management That Protects Your Competitive Position

Running a warehouse efficiently is a balancing act. Every decision, from the placement of shelves to the software you use, impacts your bottom line. We'll explore the real drivers of warehouse and distribution costs, looking beyond the obvious to uncover hidden expenses that might be impacting your profitability. This isn't about drastic cuts; it's about smart cost management that actually strengthens your business.

Understanding the True Cost of Warehousing

Many businesses focus on the big, obvious costs like rent and salaries. But what about the less visible expenses? Think of these as the "hidden costs" – things like inefficient processes or outdated tech. These can quietly drain your resources without you even realizing it.

Imagine a warehouse where the layout is a mess. Employees spend extra time hunting for products, driving up labor costs and delaying order fulfillment. This seemingly minor inefficiency adds up over time, impacting your overall profitability. Identifying and fixing these hidden costs is the key to effective cost management.

Optimizing Expenses Without Sacrificing Quality

Sure, cutting corners might save money in the short term, but it can also damage your reputation and long-term success. It's like choosing the cheapest shipping option. You might save upfront, but if deliveries are constantly late or damaged, your customers will likely find a more reliable supplier.

The trick is to balance cost savings with the quality of your service. This means finding ways to improve efficiency without impacting the customer experience.

Strategies for Sustainable Cost Reduction

Smart cost management means optimizing every part of your warehousing and distribution operations. Here are a few examples:

- Negotiating better rates with suppliers: A strong supplier relationship can lead to volume discounts and better pricing.

- Improving inventory management: Less excess inventory means lower storage costs and a reduced risk of products becoming obsolete.

- Streamlining warehouse processes: Efficient workflows save on labor and improve order fulfillment times.

- Investing in technology: While technology requires an upfront investment, the long-term return from improved efficiency and data-driven decisions can be significant.

For example, WAFF Logistics helps clients optimize their supply chain costs by analyzing their current setup, finding areas for improvement, and recommending tailored solutions. This could range from implementing a new Warehouse Management System (WMS) to redesigning warehouse layouts for faster picking and packing. By focusing on measurable improvements, WAFF Logistics helps businesses achieve real, sustainable cost reductions.

Measuring and Improving ROI

Tracking Key Performance Indicators (KPIs) like order fulfillment time, inventory turnover, and storage cost per square foot is essential. These metrics provide valuable insight into how effective your cost management strategies are.

Regularly reviewing these KPIs allows you to pinpoint areas for improvement and adapt your strategies. Imagine implementing a new picking system and then analyzing the data. If order fulfillment time significantly decreases, you know the investment was a good one. This data-driven approach ensures that cost management decisions are backed by evidence and contribute to your overall business goals.

Aligning Cost Management with Business Goals

Cost management shouldn’t be a standalone initiative; it should be integrated with your broader business strategy. For example, if you're aiming to expand into new markets, investing in a stronger distribution network might be necessary, even if it temporarily increases costs.

Aligning cost decisions with your long-term goals ensures that cost management strengthens, rather than weakens, your market position. This strategic approach lets you manage costs effectively while building a business that's both efficient and competitive. WAFF Logistics understands the specific needs of different industries, like medical equipment manufacturing and body care, providing tailored services that optimize costs while adhering to industry regulations.

Building Your Warehousing and Distribution Success Plan

Success in warehousing and distribution isn't some secret formula. It's about grasping the basics and using them cleverly. Imagine constructing a building: a solid foundation, sturdy walls, and a well-built roof are essential. Each project has its quirks, but the core principles of quality remain the same. This section offers a practical guide for crafting a winning warehousing and distribution plan, whether you're refining existing processes or starting fresh.

Evaluating Your Current Situation: Where Do You Stand?

Before making any changes, it's important to understand your current position. Think of it as getting a health check-up before embarking on a fitness regime – knowing your baseline is crucial. Evaluate your current warehouse layout, the technology you use, and your existing processes. Where are the hold-ups? What are the main frustrations for your team? Are you meeting customer expectations for delivery times and accuracy? An honest self-assessment is the first step toward improvement.

Identifying High-Impact Opportunities: Prioritizing for Success

Not all improvements are equally effective. Some will yield greater results than others. Focus on changes that will have the most significant impact. It’s about working smarter, not just harder. Is it streamlining your pick paths to minimize travel time? Could a Warehouse Management System (WMS) improve inventory control? Perhaps a more strategically located warehouse is the answer? Prioritize initiatives that address your biggest obstacles and align with your overall business objectives.

Executing Changes: Turning Plans into Reality

Having a plan is a good start, but execution is what truly matters. Think of it like running a marathon – you must pace yourself and stay focused on the finish line. Divide large projects into smaller, manageable tasks. Set realistic deadlines and monitor your progress. Keep your team involved and communicate clearly throughout. Celebrate small victories along the way to maintain momentum.

Realistic Timelines and Common Pitfalls

Recognize that different initiatives have varying timelines. Optimizing pick paths may bring quick wins, while implementing a new WMS could take several months. Be prepared for obstacles. Common pitfalls include underestimating the complexity of implementation, lack of team buy-in, and inadequate training. Anticipating these challenges helps you navigate them more effectively.

Maintaining Momentum: Sustaining Long-Term Excellence

Building a successful warehousing and distribution operation isn't a one-off project; it’s an ongoing journey. It’s like tending a garden – constant nurturing is needed for it to flourish. Continuously evaluate your performance, identify areas for improvement, and adapt to evolving market demands. Cultivate a culture of continuous improvement within your team. Discover expert strategies for reducing your supply chain’s environmental impact. Reduce Supply Chain Carbon Emissions With Expert Strategies

Building Organizational Capabilities: Empowering Your Team

Investing in training and development is like providing your team with the right tools and instruction – they'll be equipped to build a better product. Empower your team with the skills and knowledge needed for success. Define clear roles and responsibilities, and foster a collaborative work environment. Empowered employees are more engaged, productive, and dedicated to ongoing improvement. This builds the organizational strength that sustains long-term operational excellence.

Ready to optimize your warehousing and distribution operations? WAFF Logistics offers comprehensive 3PL services, from warehousing and fulfillment to local and national distribution. We provide tailored solutions for diverse industries, including e-commerce, construction, medical equipment, and body care. Contact WAFF Logistics today to discover how we can help you build a more efficient and profitable supply chain.

Article created using Outrank